- LINK BACK

-

-

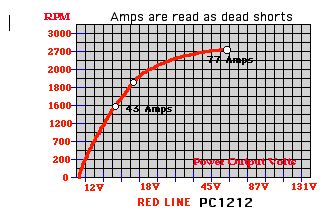

- NOTE:

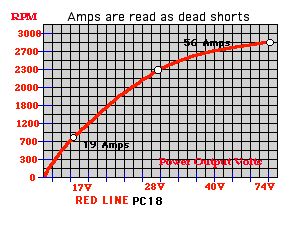

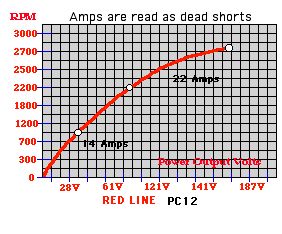

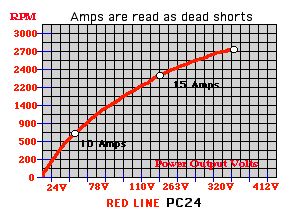

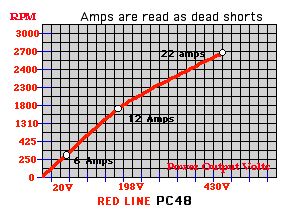

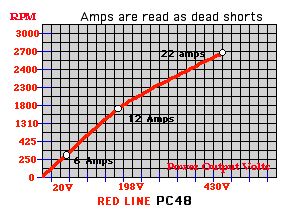

- These Ratings are ONLY to be used

as a basic guide line.

- Voltages are usually much higher

than shown so expect more.

-

- NOTE: Our model numbers have

nothing to do with voltages.

-

- 2700 RPM MAXIMUM!

- Torque Calculations:

- We have no Torque figures since Torque

is totally a function of LOAD. A PMA with no load requires ZERO

torque to turn at a ZERO load. You can't rate PMA's with simple

torque figures since "AMPS" or "LOAD" is

up to every individual situation and individual people have endless

configuration ideas for their

DRIVER and LOAD figures for whatever "Gizmo" they are

building.

-

- These is all you really need to know

is:

- 1 HP = 745 Watts / This is the conversion

figure of electrical power to mechanical power and vis-versa.

From the HP and YOUR amp load figure you can calculate any required

TORQUE figures for YOUR specific driver and YOUR specific LOAD

which WE do not know.

-

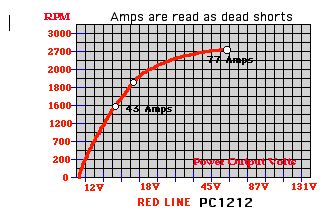

Power Core 1212

Ohms law calculator

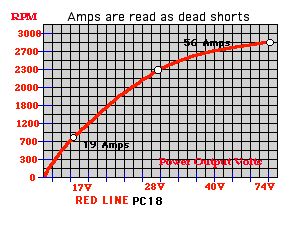

Power Core 18

Ohms law calculator

-

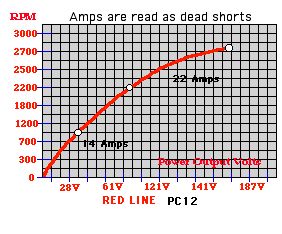

Power Core 12

Ohms law calculator

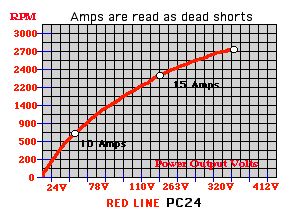

Power Core 24

Ohms law calculator

Power Core 48

Ohms law calculator

GO BACK TO PMA

SALES PAGE

NOTE: These Ratings are ONLY to be

used as a basic guide line. Voltages may be higher than shown.

-

- NOTICE FOR ANY OF YOU A.E. NOVICES OUT

THERE:

-

- A battery is basically a BIG capacitor in electronic terms.

Once your batteries are fully charged you must THEN

stop putting any additional power into it!

-

- Wind is unpredictable so

at low wind speeds you want to make sure that your PMA can still

exceed the voltage of your battery bank. (11 volts at a 200 amp

potential going into a 12 volt battery = zero charge)

-

- Tech notes:

Do not attempt to use a pulley smaller than 2 5/8" - The

belt tension required to keep the belt from slipping on a smaller

pulley will severely limit bearing life.

-

- 5 to 8 HP engines are the most popular

power choice for people trying to achieve maximum results from

their PMA's.

TECH NOTES:

TECH NOTES:

-

- Taking apart a PMA the right way.

-

- 1. Remove the 4 housing bolts and pull the front housing

off OVER the shaft. Never pull the rear housing off first!!!!

If it is jammed or rusted use some WD-40 on the shaft and alternately

tap the mounting wings with a hammer while applying pressure

to the shaft with your thumb so that the stator and it's delicate

wiring harness is kept in place. NOTE: If the shaft is scored-up

badly you may have to sand the shaft down to it's original 17mm

size to get the front housing off.

-

- 2. Now grab the exposed rotor core shaft and pull it out

WHILE holding down the stator ring with your index

- finger and thumb. This will take LOTS of strength!!!!! If

you fail to hold the stator in place the core and stator

- will be extracted together and the wires will be torn off

of the stator and this is unrepairable! This is a tricky maneuver

and usually takes some experience and lots of muscle!!!!!!!

-

- 3. Once the rotor core has been successfully extracted the

rectifier connections are exposed and you may now unfasten the

three wire nuts to safely remove the stator coil. (To reassemble

simply reverse procedure)

-

- Warranties will be void on any PMA that is opened by a customer.

- Any PMA experimentation and examination is at your own risk.

-

-

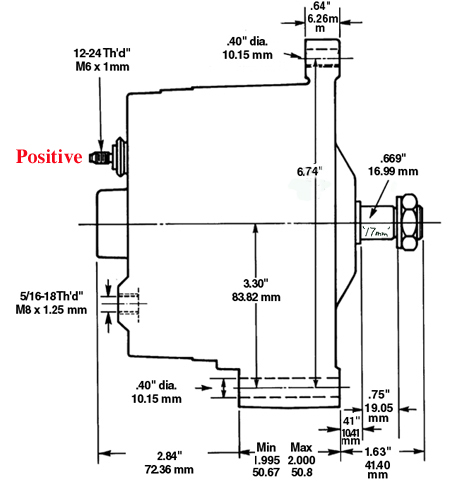

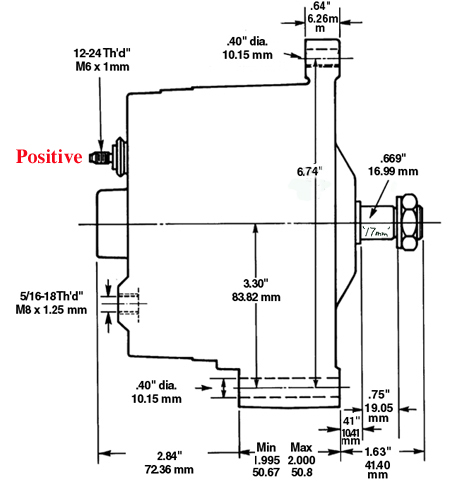

CLICK DRAWING

TO ENLARGE

-

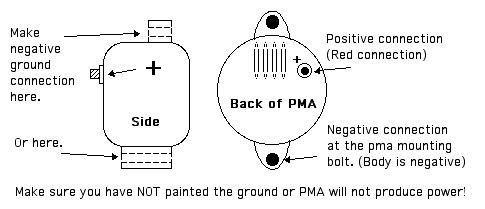

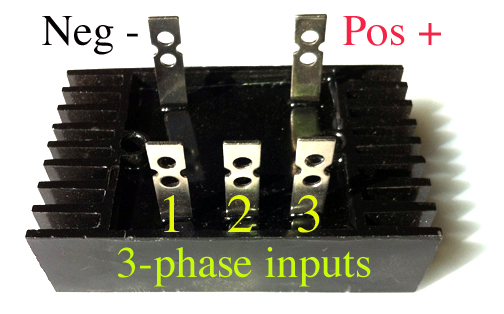

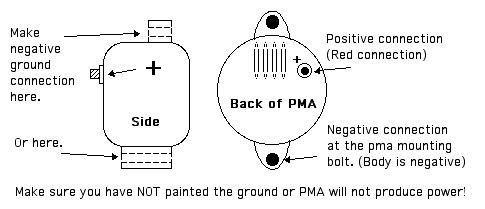

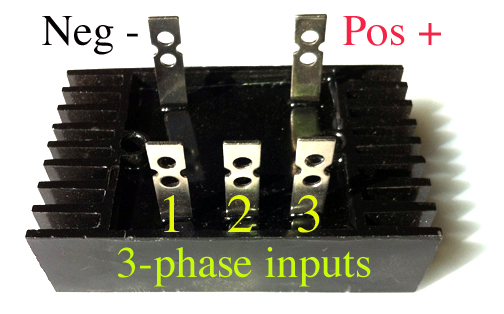

Three phase

units need a rectifier

-

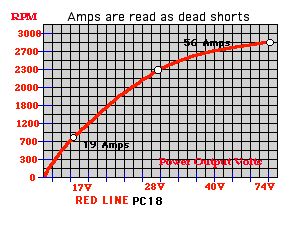

- PLEASE NOTE:

- VOLTAGES - ARE RATED WITH CIRCUIT OPEN

-

- AMPERAGES - ARE RATED WITH CIRCUIT CLOSED-

- ACTUAL CHARGING VOLTAGES

MAY VARY DEPENDING ON YOUR SPECIFIC LOAD.

- These curves show the

maximum Voltage OR Amperage

- POTENTIAL but is not showing

both SIMULTANEOUSLY!!!

- Only YOUR specific LOAD

can determine the final Wattage.

-

These PMA's have no over heat protection. These PMA's will

try to push ANY load you place on them until the coils literally

burn up. You have to exercise caution during R&D of new products

and check frequently for any over heating. You especially have

to exercise caution when using an engine or other high torque

driver to turn them. Use the proper circuit breaker and wire size

for your load. It is very easy and very tempting to operate them

past their over heating limits but be warned if you burn up a

PMA it is going to be your fault and not ours so watch them very

carefully during R&D for over heating!!!!! No warranties on

any burned up PMA's!!! If they start smoking or making a burning

smell your load is simply too large for the speed your are operating

at. Running them slower or reducing the load may work in some

applications! However the problem may also be that you are running

them so slow that the cooling fan does not pull enough air into

the case. The solution is to run at a faster RPM and reduce amperage

load until it runs cooler. They normally do run hot averaging

250 degrees + in most applications but they should not smoke or

make a burning smell. When coil varnish starts burning it is an

obvious smell. Use a wiring guide chart and select the proper

sized wire for your amperage and voltage requirements. Inspect

the coils during R&D. If the coils vanish has turned black

they have been run with an excessive amperage load for that RPM

range. Inadequate sized wire can cause excessive loads on your

PMA coils especially in 12 volt charging applications!

- Power at max amps is rated

as a DEAD SHORT on our charts! That is to be used as a guide

line sine we DO NOT know your loads in ohms.

- To operate at a dead short

is impossible so figure roughly 25% of this amperage at a 80%

duty cycle or 20% at a 100% duty cycle.

- As a rule you may never

set the RPM so that these PMA's are making over 2000 watts! To do so would over heat the coils.

-

-

- 2700 RPM MAXIMUM!

-

NOTE: PMA's used with engines driving

them require a fan kit for cooling.

- WARNING: IF you are pulling over

300 Watts without a cooling fan your PMA it will over heat! Fan

kits are very important to have on ALL high amp applications!!!!---

Keeping your PMA's cooled, fused and under reasonable loads is

the operators full responsibility. Monitor your PMA for excessive

heating in all experimental machinery! Maximum PMA's operating

temperature is 350 F. for 100% duty cycle. No warrantee's on

ANY burned out PMA's! They are sold in good working condition

and you have to keep them cool and never over loaded regarding

amperage draw.

-

- A PMA RUNNING SLOW AND DRAWING FULL

AMP LOAD IS A DEAD PMA!

- Here is a buying guide to help you

choose the right PMA and keep it cool.

-

- Following these figure are ONLY a guide

and is not a guarantees cool operation since your amp load can

still be to extreme. Don't pull more amperage then they can handle.

If you burn one up you own it!!! No warranties on burned up PMA's!!!

All sales Final. If you are an amateur and do not understand

electrical windings and how much heat they can take please don't

buy one of our PMA's. If you are experienced watch for over heating

and be careful.

-

- PLEASE NOTE: Our model numbers have

nothing to do with voltages. For instance, our model #120 series

can make 1,400 volts if you spin it at 18,000 RPM or it can make

12 volts if you spin it at 200 RPM. The '120' code is ONLY a

stock number as are ALL the model numbers in ALL our PMA's. Our

model numbers (#) are NOT voltage designations!

-

- #HD series PMA's produce unregulated

D.C. voltage and may require a charge

controller for smaller batteries banks or non-grid connected

applications.

-

-

- Battery

regulator / Dump load regulator

-

- Regulate your BATTERY instead

of your wind turbine, solar panels or any AE devices.

-

-

- See http://www.outbackpower.com

grid tie systems and more info

on spinning your power meter backwards.

-

- (PMA's have no over heat protection. Please use the appropriate

fuses to protect your PMA coils)

-

- Permanent Magnet Alternators PMA Permanent

Magnet Alternator Permanent Magnet generator wind power PMG wind

turbine wind turbinesPermanent Magnet Alternators PMA Permanent

Magnet Alternator Permanent Magnet generator wind power PMG wind

turbine wind turbinesPermanent Magnet Alternators PMA Permanent

Magnet Alternator Permanent Magnet generator wind power PMG wind

turbine wind turbinesPermanent Magnet Alternators PMA Permanent

Magnet Alternator Permanent Magnet generator wind power PMG wind

turbine wind turbinesPermanent Magnet Alternators PMA Permanent

Magnet Alternator Permanent Magnet generator wind power PMG wind

turbine wind turbines

- Hit 92[an error occurred while processing this directive]-Times

-

-

- [an error occurred while processing this directive]

TECH NOTES:

TECH NOTES: